Steel production is a difficult-to-mitigate sector that challenges climate mitigation commitments. Efforts for future decarbonization can benefit from understanding its progress to date. Here we report on greenhouse gas emissions from global steel production over the past century (1900-2015) by combining material flow analysis and life cycle assessment. We find that ~45 Gt steel was produced in this period leading to emissions of ~147 Gt CO2-eq. Significant improvement in process efficiency (~67%) was achieved, but was offset by a 44-fold increase in annual steel production, resulting in a 17-fold net increase in annual emissions. Despite some regional technical improvements, the industry’s decarbonization progress at the global scale has largely stagnated since 1995 mainly due to expanded production in emerging countries with high carbon intensity. Our analysis of future scenarios indicates that the expected demand expansion in these countries may jeopardize steel industry’s prospects for following 1.5 °C emission reduction pathways. To achieve the Paris climate goals, there is an urgent need for rapid implementation of joint supply- and demand-side mitigation measures around the world in consideration of regional conditions.

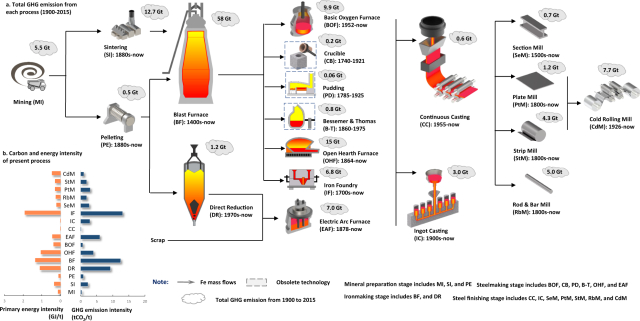

a The connection of 19 dominating processes with their representative production technologies, application period and total carbon emissions from 1900 to 2015. b Energy intensity and carbon intensity level for each process (for details see Supplementary Information 1 Section S2.2). Abbreviations for steel production flows are: MI mining, SI sintering, PE pelleting, BF blast furnace, DR direct reduction, BOF basic oxygen furnace, CB crucible, PD puddling, B-T Bessemer & Thomas, OHF open-hearth furnace, IF iron foundry, EAF electric arc furnace, CC continuous casting, IC ingot casting, SeM section mill, PtM Plate Mill, StM strip mill, RbM rod bar mill, CdM Cold rolling mill.